We are leading manufacturers and pioneers in clay brick manufacturing, since 1970’s.

+92 321 5522247 , +923004701880Whatsapp : +92 321 5522247

Email: [email protected]

Vital Bricks

23 Km Multan Road Lahore, Pakistan

WE ARE

We are leading manufacturers and pioneers in clay brick manufacturing, since 1970’s. We have export back ground and locally covering some major and significant projects are

- Karachi steel Mill

- Lahore Airport

- Lums University

- Al hamra Hall

- Holiday Inn

- GPO Lahore

- Shaukat khannam hospital

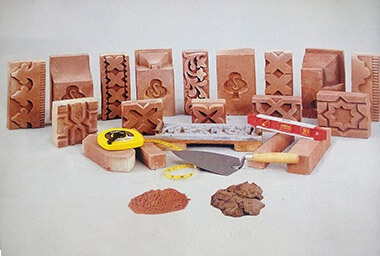

Striving to give you best quality, economy and prompt delivery. Having wide range of designs with customized sizes.

BRICK PRODUCTION

Basically the process of brick making has not changed since the first fired bricks were produced some thousand years ago.

The steps used then are used today, but with refinements. The various phases of manufacturing are as follows

i. Securing the clay

ii. Beneficiation

iii. Mixing and forming

iv. Drying

v. Firing and cooling

SECURING THE CLAY

Clays used in brick making represent a wide range of materials that include varying percentage of silica and alumina. They may be grouped in three classes.

(a) Surface Clay

Mostly bricks in Pakistan are made from surface clays, which are 3 to 4 feet in depth.

(b) Shale’s

These clays are obtained from decomposed rock, may he near mountain areas.

(c) Fire-Clays

Found deeper under the surface. These fire clays have more uniform chemical composition than surface or shale

BENIFICATION

Raw clays are often blended to obtain a uniform consistency. The clay is then passed from grinders and screens to secure the optimum particle size for mixing with water.

MIXING & FORMING

There are three basic process used in mixing and forming phase:

a) Extruded Bricks

In this stiff mud process the clay is mixed with water to render its plastic after which it is forced through a die that extrudes a column of clay like toothpaste. The column gives two dimensions of the unit: it is cut by the wire to give the third dimension.

b) Molded Bricks

The older method of forming the brick, the soft mud process much more water is used. The mix is put in wooden or steals moulds to form the size unit required. Moulds are lubricated with sand or water. These are called sand struck or water struck bricks.

c) Pressed bricks

Clays with very low plasticity are used in the dry press-process.

DRYING

After the bricks are formed, they must be dried to remove as much as free water as possible. Drying a part from sun drying is done in direct dryers with controlled temperatures draft and humidity.

FIRING & COOLING

Bricks are fired and cooled in a kiln an oven type chamber capable of producing temperatures 870C to 1100C (1600-2000f) Depending on the type of raw material.

There are two types of kilns

i) Periodic

ii) Continuous

QUALITY CONTROL

The testing of materials is one of the important requirements of civil work from quality control point of view.

Standard tests for brick are as follows:-

1) CRUSHING STRENGTH TEST

2) WATER ABSORPTION TEST

3) EFFLORESCENCE TEST

4) EFFLORESCENCE AFTER CONSTRUCTION

5) DIMENTIONAL TEST